Choosing the Right Software

Whether you are outgrowing entry-level software or replacing a legacy system, choosing an ERP that is a good fit for your company can have a strong impact on your future growth and pro tability. Because the cost of implementing an ERP is so high, demanding a great deal of time and input from employees across your organization as well as potentially significant software licensing and consulting fees, there is tremendous pressure to get it right the first time.

Despite these high stakes, most decision makers selecting and implementing ERP software will not do so more than a few times in their career. The purchasing relationship is therefore tilted in favor of the vendor, with many vendors requiring hours of qualification before revealing crucial details such as features and pricing. When dealing with vendors, it is therefore essential to accurately and completely communicate the needs of your organization to avoid finding out 6 months into implementation that the project isn’t feasible or that an unexpected and expensive custom development is required.

Cloud or On-Premises?

In recent years there has been a trend in business software towards a software as a service (SaaS) model. Most major business software vendors, ERP or otherwise, have begun offering their locally installed products in a cloud-hosted version to provide additional flexibility. When deploying a cloud-based software, there is no need for a local server or other network hardware as data is managed and processed on a secure off-site server which, depending on the size of the deployment, can significantly reduce the initial cost of a system. This can make a cloud solution a better choice for small and medium size businesses with less capital.

Microsoft Dynamics AX

“ BUSINESS SOLUTIONS TAILORED TO YOUR NEEDS ”

Microsoft Dynamics AX is most feature-rich of the five products in the Microsoft Dynamics ERP line. AX was originally released as a collaboration between IBM and Daamgard Data as IBM Axatpa in 1998 before being acquired by Microsoft in 2002 and rebranded under its current name.

AX is designed for mid-to-enterprise size businesses operating across multiple locations, countries, or currencies. Dynamics AX has particular strengths in manufacturing and distribution. It is commonly deployed by companies with revenue greater than $50 million annually, though smaller implementations are also possible. It is commonly used by discrete manufacturers, though it is also deployed by process manufacturers and in the retail industry. AX is offered both in the cloud and as an on-premises installation, sold exclusively by value-added resellers. For this comparison, we chose the latest release, AX 2012 R3, in the on-premises configuration.

Odoo Online

“ GROW YOUR BUSINESS ”

Odoo is an open-core suite of business apps. It is built on a modular structure in which each app covers one business function and each app is installed as needed.

Odoo is available to be installed on-premises as well as in the cloud.

Odoo recently released a new version of its manufacturing app suite, adding quality, maintenance, PLM, and expanded mrp and mes functionality. In this document, we will compare the on-premises con guration of the latest release, version 10.

Support and implementation services for the on-premises edition are sold by Odoo certified partners, while support for the SaaS is provided by Odoo Inc. itself. The on-premises edition has thousands of community-developed modules which add or modify functions, allowing a high degree of exibility. The first-party SaaS only allows the installation of the three-dozen modules officially supported by Odoo Inc.

Features Comparison

Inventory Management |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| General | |||

| Multi-Warehouse | |||

| Storage Locations

(Bins) |

|||

| Bin Replenishment | |||

| Mobile Device Support | |||

| Multi-Company | |||

| Multi-Currency | |||

| Multi-Language | |||

| Automatic ASN

(Advanced Shipping Notice) |

|||

| Package Management / Cartoning | |||

| Freight Carrier Integration | |||

| Manage Consignee Stocks | |||

| EDI

(Electronic Data Interchange) |

* | * | |

| Products | |||

| Non-Stocked Inventory * | |||

| Multiple Variants | |||

| Multiple Units of Measure | |||

| Inter-class UoM Conversion * | |||

| Variant Matrix | |||

| Traceability | |||

| Lots / Serials | |||

| Up / Down Traceability | |||

| 360° Traceability * | |||

| Expiration Dates | |||

| Cycle Counting | |||

| Reporting | |||

| Inventory Forecasts | |||

| Inventory Valuations | |||

| ABC Analysis | |||

| Barcode Support | |||

| QR Code Support | * | ||

| RFID Support | * | ||

| Lots / Serial Numbers | |||

| Receptions | |||

| Picking | |||

| Internal Moves | |||

| Delivery Orders | |||

| Inventory Adjustments | |||

| Routing | |||

| FIFO / LIFO | |||

| Customizable Routes * | |||

| Putaway Strategies | |||

| Wave Picking | |||

| Batch Picking | |||

| Zone Picking | |||

| Cluster Picking | |||

| Cross-Docking | |||

| Putaway Location By Size, Weight, & Capacity | |||

Supply Chain |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| Features | |||

| Vendor Data Management | |||

| Vendor Pricelist Management | |||

| Inbound Quality Control | |||

| Dropshipping | |||

| Purchases | |||

| Purchase Requests | |||

| Purchase Orders | |||

| Purchase Approval Worflow | |||

| Request for Quotations | |||

| Contracts / Purchase Agreements | |||

| Automated Procurements | |||

| Minimum Stock Rules * | |||

| Make-to-Order | |||

| Master Production Schedule | |||

Manufacturing |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| Master Data | |||

| Multi-Level BoM | |||

| Byproducts / Coproducts | |||

| Routings | |||

| Subassemblies | |||

| One BoM for Multiple Product Variants | |||

| BoM versions | |||

| Multiple BoM / Routing * | |||

| Planning | |||

| Demand Forecasting | |||

| MRP I Scheduler | |||

| MRP II Scheduler * | |||

| Master Production Schedule | |||

| Gantt Chart Scheduling w / Drag & Drop | |||

| Kanban Planning | |||

| Production Calendar | |||

| Infinite Capacity Scheduling | |||

| Finite Capacity Scheduling | |||

| Available to Promise | |||

| Multiple Scheduling Plans | |||

| Delivery Date Calculation

(Backwards Scheduling) |

|||

| Production Order Splitting / Merging | |||

| Operations | |||

| Manufacturing / Production Orders | |||

| Job Tracking | |||

| Work Orders / Operations | |||

| Automated Time Tracking | |||

| Disassembly Orders | |||

| Subcontract Manufacturing | |||

| Rework / Repair | |||

| Scrap | |||

| Disposal Strategies | |||

| Kits | |||

| Edit Individual Production BoMs | |||

| Costing | |||

| Perpetual Inventory Valuation * | |||

| Periodic Inventory Valuation * | |||

| Standard Price | |||

| FIFO | |||

| Landed Costs | * | ||

| Actual Production Labor | |||

| Production Order Costing | |||

| Shop Floor Control | |||

| Shop Floor Terminals | |||

| Production Activities | |||

| Non-Produciton Activities * | |||

| Time Tracking | |||

| Messages on Work Orders | |||

| Barcode Support | |||

| Equipment / Machine Management | |||

| Work Instructions on Work Orders | |||

| Maintenance Requests from Shop Floor Terminal | |||

| Human Resources | |||

| Schedule Management | |||

| Touchscreen Attendance | |||

| Timesheets | |||

| Breaks | |||

| Overtime | |||

| Vacation / Injury | |||

| Reporting and Forecasting | |||

| Overall Equipment Efficiency | |||

| Work Time | |||

| Demand Forecast | |||

| Maintenance KPIs | |||

| Production Costs Analysis | |||

| Up / Downstream Traceability | |||

| Analytic Accounting | |||

| CSV Export | * | ||

| Dynamic Pivot Tables | |||

| Dashboards | |||

| Save Custom Reports | |||

Maintenance |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| Scheduling and Request Handling | |||

| Schedule Preventive Maintenance | |||

| Maintenance Kanban | |||

| Maintenance Calendar | |||

| Shop Floor Integration | |||

| Multiple Teams / Sites | |||

| Asset Management | |||

| Subcontract Repair | |||

| Job Tracking | |||

| Parts Management | |||

| Inventory Management | |||

| Purchasing Integration | |||

| Rotating Asset Location | |||

| Equipment Serial Numbers | |||

| Equipment Maintenance History | |||

| Dealer Portal | |||

QMS |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| Quality Control | |||

| At Reception | |||

| In-Process | |||

| Before Delivery | |||

| Inventory Quarentine | * | ||

| Quality Checks | |||

| Quality Control Plan | |||

| Pass / Fail Checks | |||

| Measurement Checks | |||

| Quality Alerts / Nonconformance Documents | |||

| Print Nonconformance Documents | |||

| Corrective Actions | |||

| ISO9001 Tools | |||

| Documentation Management | |||

| Customer Satisfaction Surveys | |||

| Customer Complaints Management | |||

| Traceability of Operations | |||

| Resources Management | |||

| Reports | |||

| Nonconformance Costs | * | ||

Product Lifecycle Management |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| Features | |||

| Engineering Change Orders

(ECOs) |

|||

| BoM Version Management | |||

| Routing Version Management | |||

| MRP Integration | |||

| Centralized BoM Management | |||

| ECO Management | |||

| Approval Workflows | |||

| BoM Version Difference Viewer | |||

| Bulk BoM Updates | |||

| Notification Mechanism | |||

| Project eMail Gateway | |||

| ECO Costing | |||

| Third-Party CAD Integrations | |||

| AutoCAD | |||

| SolidWorks | |||

| Autodesk | |||

User Interface

Usability, especially in enterprise software, is an often-overlooked but critically important aspect to consider during the purchasing process. Usability affects the efficiency of users working within the system, the ease with which the software can be implemented, and can reduce the costs associated with user errors. Additionally, users who spend most of their working day using the system will appreciate software that is easy to use. This is especially true for shop floor control systems, as workers there may be in a loud environment, moving quickly, wearing PPE, or otherwise not optimally situated to use a traditional computer interface with a keyboard and mouse. The special design considerations of a shop space or production line must be taken into consideration for any interface used there.

We have selected screenshots of analogous menus within each software to demonstrate the visual elements and interface options for each software in this comparison. While it is difficult to assess software usability with a static image, a rough comparison can be made. The additional information can only aid your analysis.

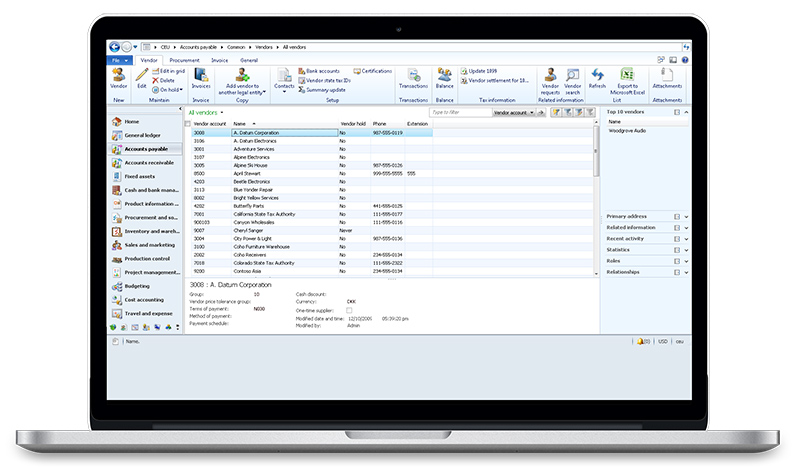

User Interface - Microsoft Dinamycs AX

Microsoft Dinamycs AX - Dashboard

Microsoft Dinamycs AX - List of Vendors

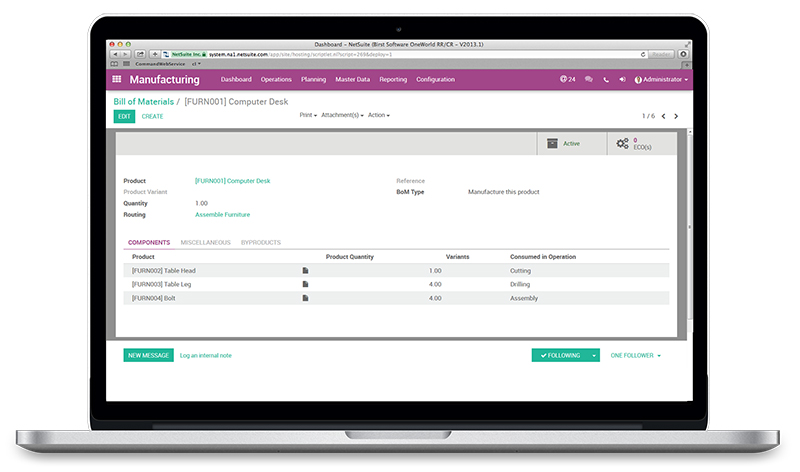

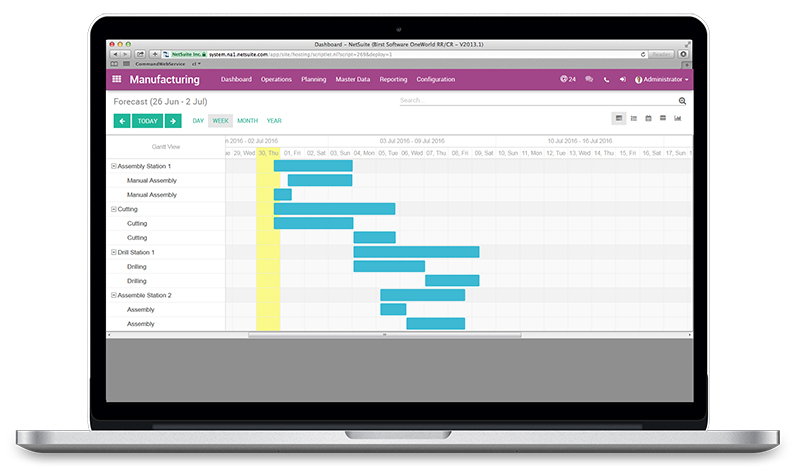

User Interface - Odoo

Odoo - BoM

Odoo - Production Scheduling

Usability & Productivity |

Odoo

|

Microsoft

|

|

|---|---|---|---|

| UI | |||

| Full Web Interface | * | ||

| Responsive Mobile UI | |||

| Android Native App | |||

| iOS Native App | |||

| Market Place | |||

| App Store / Add-ons | * | ||

| Subjective Ratings | |||

| Ease of Use | |||

| Navigation and Search | |||

| Data Entry | |||

| Mobile App | |||

| Reports Flexibility | |||

Customer Satisfaction

Ratings |

Microsoft

|

Odoo

|

|---|---|---|

| G2crowd rating | 4.4/5 | 4.1/5 |

| GetApp rating | 5/5 | 5/5 * |

| Capterra rating | 5/5 | 4.5/5 * |

| Capterra rating |

Pricing & Conditions

Pricing & Conditions |

Odoo

|

Microsoft

|

|---|---|---|

| PRICING * | $25 / user / month | $2,000 - $6,000 / user |

| Contract Duration | Monthly / Annual | Perpetual |

| Five Year Cost, 50 Users | $75,000 | $100,000 - $300,000 |

| Free Trial | * | |

| New Version Upgrades Included | ||

| Update Service Included | ||

| Cloud Offer Available |

Conclusion

Many factors must be considered when choosing a manufacturing software. The complexity of the production workflow, the degree to which demand fluctuates, the lead times of production and procurement, the size of the organization, the growth rate of the business, the stockkeeping needs, the complexity of the support operations in a plant. The list, as they say, goes on. You must make the decision based on your own superlative knowledge of your business while working closely with whichever vendor you choose.